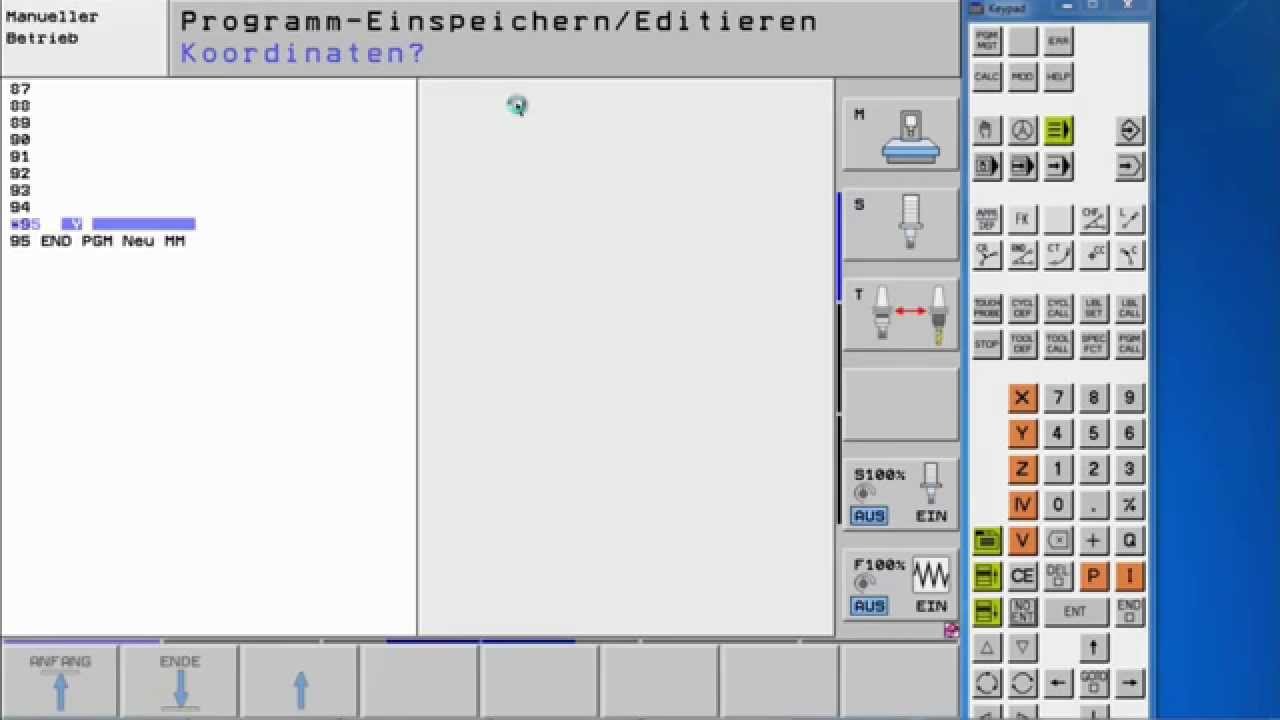

Heidenhain Itnc 530 Simulator Full

Hi, I realize that you are facing an issue with the iTNC 530 CNC simulator. I will try to help you with this issue. Plug in the device and run the hardware.

. User’s Manual HEIDENHAIN Conversational Format iTNC 530 NC Software 606420-04 SP8 606421-04 SP8 606424-04 SP8 606425-04 SP8 English (en) 3/2016. Controls of the TNC Program/file management, TNC functions Keys on visual display unit Function Function Select or delete programs and files, external data transfer Select split screen layout Define program call, select datum and point tables Toggle the display between machining and programming modes Select MOD functions Soft keys for selecting functions on.

Tool functions Coordinate axes and numbers: Entering and editing Function Function Define tool data in the program Select coordinate axes or. Enter them into the program Call tool data Numbers. Decimal point / Reverse algebraic sign Programming path movements Function Polar coordinate input / Incremental. Would you like any changes, or have you found any errors? We are continuously striving to improve our documentation for you. Bionaire tower fan manual. Please help us by sending your requests to the following e-mail address: tnc-userdoc@heidenhain.de. HEIDENHAIN iTNC 530.

User's Manual for Cycle Programming: All of the cycle functions (touch probe cycles and fixed cycles) are described in a separate manual. Please contact HEIDENHAIN if you require a copy of this User's Manual. ID: 670388-xx smarT.NC user documentation: The smarT.NC operating mode is described in a separate Pilot. Software options The iTNC 530 features various software options that can be enabled by you or your machine tool builder. Each option is to be enabled separately and contains the following respective functions: Software option 1 Cylinder surface interpolation (Cycles 27, 28, 29 and 39). AFC software option Description Function for adaptive feed-rate control for Page 440 optimizing the machining conditions during series production.

KinematicsOpt software option Description Touch-probe cycles for inspecting and User’s Manual for optimizing the machine accuracy Cycles 3D-ToolComp software option Description 3-D radius compensation depending on the Page 536 tool’s contact angle for LN blocks. Adaptation of control parameters Machine Manual Load Adaptive Control (LAC) software Description option Dynamic changing of control parameters Machine Manual Active Chatter Control (ACC) software Description option Fully automatic function for chatter control Machine Manual during machining HEIDENHAIN iTNC 530. You can purchase a code number in order to permanently enable the FCL functions. For more information, contact your machine tool builder or HEIDENHAIN. FCL 4 functions Description Graphical depiction of the protected. EN 55022, and is intended for use primarily in industrially-zoned areas.

Legal information This product uses open source software. Further information is available on the control under Programming and Editing operating mode MOD function LEGAL INFORMATION SOFT KEY HEIDENHAIN iTNC 530. New functions in version 60642x-01 since the predecessor version 34049x-05 Opening and editing of externally created files has been added (see 'Additional tools for management of external file types' on page 146) New functions in the task bar have been added (see 'Task bar' on page 96) . The tool sequence list includes more detailed information now The loading and unloading list of the tool magazine can now be loaded and unloaded by drag and drop Columns in the table view can be moved simply by drag and drop HEIDENHAIN iTNC 530. Several special functions (SPEC FCT) are now available in the MDI operating mode (see 'Programming and executing simple machining operations' on page 624) There is a new manual probing cycle that can be used to compensate workpiece misalignments by rotating the rotary table (see 'Workpiece alignment using 2 points'. (see 'Setting up the pallet level' page 556 ff) If a tool sequence list is created for a pallet table, the TNC now also checks whether all the NC programs of the pallet table are available (see 'Calling the tool management' on page 205) HEIDENHAIN iTNC 530. The new host computer operation was introduced (see 'Host computer operation' on page 698) The SELinux security software is available (see 'SELinux security software' on page 97) Improvements to the DXF converter: Contours can now also be extracted from.H files (see 'Data transfer from plain-language programs'.

Return of the offset errors (change of machine datum) to the parameters Q147-149 More plane measuring points for ball measurement Rotary axes that are not configured are ignored by the TNC when executing the cycle HEIDENHAIN iTNC 530. New functions in version 60642x-03 New software option Active Chatter Control (ACC)(see 'Active Chatter Control (ACC—software option)' on page 451) Improvement of Dynamic Collision Monitoring (DCM): For the NC syntax SEL FIXTURE, the software now supports a selection window with file preview for selecting saved fixtures (see 'Loading fixtures under program control'. (see User's Manual for Cycle Programming). With Cycle 257, CIRCULAR STUD, a parameter is now available with which you can determine the approach position on the stud (see User's Manual for Cycle Programming) HEIDENHAIN iTNC 530. New functions in version 60642x-04 A new NC syntax was introduced for controlling the AFC function (adaptive feed control) (see 'Recording a teach-in cut' on page 443) You can now use the global program settings to perform handwheel impositioning in a tilted coordinate system (see 'Handwheel superimposition'.

Heidenhain Troubleshooting

(see User's Manual for Cycle Programming) Cycle 254: With Cycle 254, Circular Slot, a parameter is now available with which you can define the feed rate reference when machining the slot (see User's Manual for Cycle Programming) HEIDENHAIN iTNC 530.